Description: The use of 3D Printing in manufacturing has grown rapidly over the past few years. However, because 3D printing is an exciting method of manufacturing it doesn’t necessarily mean it makes sense to use in every business.

3D PRINTING IS THE FOUNDATION OF INDUSTRY 4.0 IN THE UAE

“With additive manufacturing, we are about where personal computing was in 1983” said Jack Beuth, a professor in the Department of Mechanical Engineering at Carnegie Mellon University’s College of Engineering, he continued saying “Companies are now trying to exploit the technology to become more profitable, and how they do it will involve innovations that are much more than just replacements for traditional manufacturing,”

The use of 3D Printing in manufacturing in Dubai has grown rapidly over the past few years. However, because 3D printing is an exciting method of manufacturing it doesn’t necessarily mean it makes sense to use in every business. 3D Printing has been overhyped in our region and there has been a lot of misinformation surrounding the technology. This does not negate the fact that 3D Printing is of value to the majority of industrial and manufacturing organziations. As per a recently published report by PwC on 3D printing stated “3DP is evolving as a practical alternative for both product development and conventional manufacturing”. The question is not whether a company should invest in 3D printing but rather how best can company leverage and utilize this manufacturing technology.

3D Printing is one of the key pillars of Industry 4.0, where IT merges with manufacturing resulting in digital manufacturing which is the next manufacturing revolution. Any company not currently exploring and investing in 3D printing is already falling behind in competitiveness.

Today over 18% of manufacturing companies use 3D printing and the rate of adoption is rapidly increasing. A.T. Kearny, estimates that global 3D Printing industry will exceed US$17billion by 2020. While Pwc Strategy& report states that 3D Printing is entering an era of major growth with the industrial market for 3D printed products and technologies expected to exceed US$26bln within a decade.

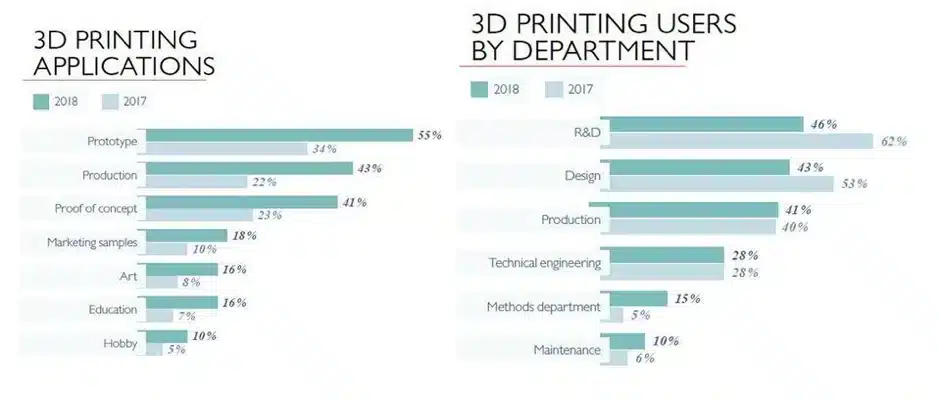

3D PRINTING APPLICATIONS

The areas where 3D printing has proven to be effective and feasible over the past decade are;

- Prototyping and Product Development;

- Low-Volume manufacturing;

- Production-grade Mechanical Parts manufacturing; and

- Medical applications (implants, models, guides, dental, etc.).

Source: PwC Strategy&

Immensa Technology Labs based out of Dubai, UAE has the largest team of additive manufacturing engineers in the GCC with over fourteen 3D printing experts. We tapped into our team’s experience to understand the challenges that face companies in the UAE, Saudi Arabia, Kuwait and rest of GCC when it came to adopting 3D Printing and how best to address those challenges.

By studying organizations that have struggled in successfully implementing 3D printing over the past decade, certain trends appeared;

- Selecting the right 3D Printing technology: There are seven main and distinct 3D printing technologies, each with its own advantages and limitations (such as SLS, FDM, SLA, etc.). Identifying the right technology is vital for successful adoption. It has been shown that an organization requires access to a number of different technologies to best utilize 3D Printing.

- Choice of materials: For successful conversion of a part from conventional production to 3D Printing, the properties of the part and its functionality are more important than matching the same material used in the conventional production process. This is a key element in 3D Printing that is regularly overlooked. Conventional part production is limited by the manufacturability of a material, 3D Printing provides freedom from existing manufacturing processes, alternative materials should be explored.

- Consistency of production and repeatability: Two production runs on the same 3D Printing system using the same designs to produce the same part, does not always produce identical parts in terms of properties. This is one of the primary challenges in 3D Printing and to mitigate this, deep knowledge and experience in parameter controls and production process control are critical.

- Limited expertise: The number of people experienced in using 3D printing for production is limited in the UAE, Saudi Arabia, Kuwait and rest of Middle East. Production-grade parts produced using 3D Printing requires specific expertise based on technology selected. 3D Printing typically requires a high degree of trial and error to help engineers and manufacturers learn what works and what does not. This expertise can be obtained via retaining specialized Additive Manufacturing consultants or through years of on-hand 3D Printing operational experience.

- Design for Additive Manufacturing (DfAM): Extremely critical aspect of 3D Printing, which needs to be invested in by organizations. Designing parts and components for conventional manufacturing diminishes significantly the value add of 3D Printing. By redeveloping and redesigning parts specifically for the 3D Printing technology on-hand is where the value of 3D Printing is maximized. The fact that there are multiple 3D Printing technologies only adds complexity to the skill sets required by mechanical and industrial engineers trying to design for 3D Printing.

- Cost of equipment: The investment necessary for production with 3D Printing is high, and companies often need to hire trained personnel to operate and maintain the machinery and set-up dedicated facilities for the 3D Printing systems. Expectations have to be managed, and adequate diligence has to be done to assess the business value of adopting 3D Printing. Outsourcing production until product development is proven is one way to tackle this issue.

Many companies in the GCC realize they should be doing something in 3D Printing, but find it challenging to get started and determine which of their products and applications are best suited for 3D printing. Over the past 3 years, Immensa Technology Labs team in the United Arab Emirates has been learning from partners and customers on how to best tackle and mitigate the above challenges. Immensa’s experienced Additive Manufacturing engineers work very closely with some of the world’s top 3D Printing companies enabling them to develop best practices that allow organizations to smoothly and cost-effectively transition into 3D Printing and integrate the technology into their operations.

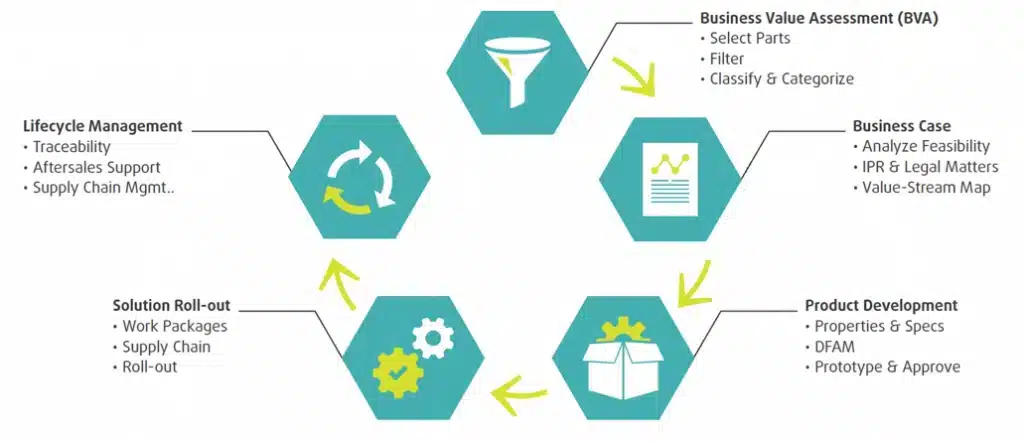

IMMENSA TECHNOLOGY LABS MULTI STEP ADDITIVE MANUFACTURING INTEGRATION PROCESS

Source: Immensa Technology Labs

Immensa is a service provider that assists organizations in implementing 3D Printing. The 3 pillars that comprise the core of our company are:

- Immensa’s proprietary database of thousands of mechanical and industrial parts designed and developed in-house specifically for 3D Printing – which provides extensive knowledge, expertise and reference for new parts being developed for clients;

- Largest 3D Printing facility in the UAE and GCC region with over 12 industrial 3D Printers, allowing the team to design and test parts before approving them for final production to the clients;

- Leading team of 3D Printing experts with specialists across different 3D Printing technologies and materials.

We work very closely with clients to identify and understand the true cost Impact of adopting 3D Printing into their businesses. We manage the entire lifecycle from initial assessment to turnaround solution of Build-Operate-Transfer. With proper stepped integration, 3D Printing should produce parts at a higher return on investment (ROI) than the conventional manufacturing process.

3D Printing is going to disrupt whole value chains, and as witnessed over the past decade it has been embraced by companies of all sizes across all sectors. Ensuring the optimal process of integrating technology is a key factor in determining the rate of success, not very different from implementing an ERP system.

In conclusion, Harvard Business Review noted the following.

“Many companies are intrigued by the potential of additive manufacturing but wary of the risks. At most they use it to make prototypes and a few low-volume niche products. Now is the time to take it seriously as an option for large-scale commercial production. Companies should move off the sidelines, get familiar with the new techniques, and explore how they might alter the competitive landscape.

Additive has the potential to shake up not just individual industries but the manufacturing sector as a whole. Eventually a technology that engineers once mocked for its slowness may become a dominant force in the economy.”

To learn more contact our experts at+971 4 443 1538 or engineering@immensalabs.com.